When choosing the right diamond tooling for your concrete grinder, understanding the difference between beveled and non-beveled segments can make a big impact on your results.

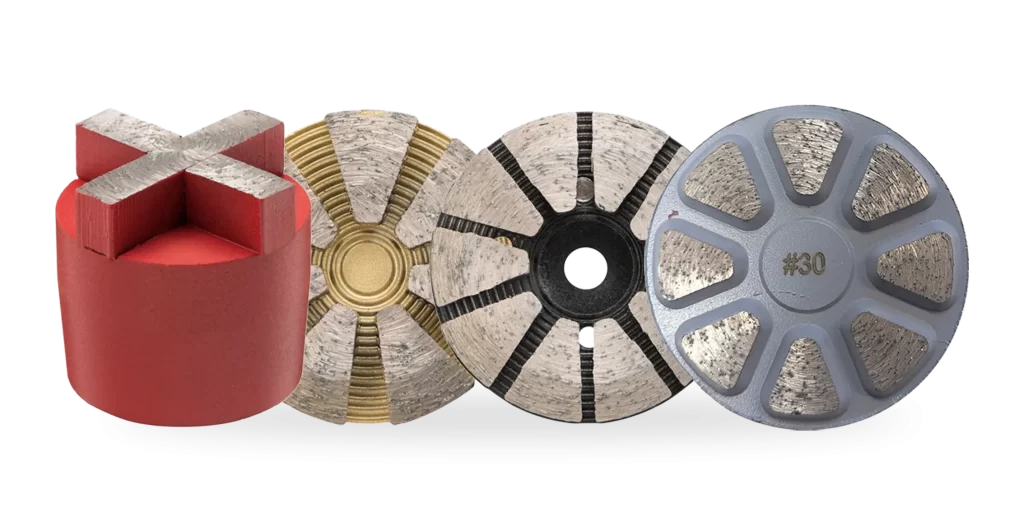

Beveled Segments

Best for: General concrete grinding and uneven surfaces.

Beveled segments taper rather than cut sharply into the surface, allowing your machine to glide smoothly over cracks, joints, and edges. This design minimizes chipping, reduces wear on gears and belts, and delivers a more forgiving grind. Beveled tooling is also ideal for uneven floors and helps reduce scratch patterns, especially if you’re prepping for a polished finish.

Non-Beveled Segments

Best for: Light coating removal and general grinding.

Non-beveled segments provide a flatter surface and more direct contact with the concrete. This increased surface area is great for heavier grinders, allowing them to grind efficiently without creating deep scratches. Non-beveled tooling works well when removing light coatings and doing fast, consistent grinding over flat slabs.