When it comes to diamond tooling for concrete grinders, segment shape, size, and bond type all play critical roles in performance. The industry standard segment size is typically 40mm long by 10mm wide, but smart adjustments to that design can make a big difference in how efficiently your tool cuts.

The Rapida Segment: Power in Precision

The concept behind the Rapida segment was built on a simple but powerful idea: reduce the segment’s surface area to increase downward pressure. Less contact area means more focused force per diamond, which helps the tool cut into hard concrete more aggressively and effectively.

The Rapida is a premium metal bond segment, featuring a soft bond and high-quality diamond matrix. Precision grooves are cut into the segment to reduce its footprint and maximize pressure. This design delivers faster, cleaner grinding, especially when opening up hard or dense concrete slabs.

Why Segment Shape and Bond Matter

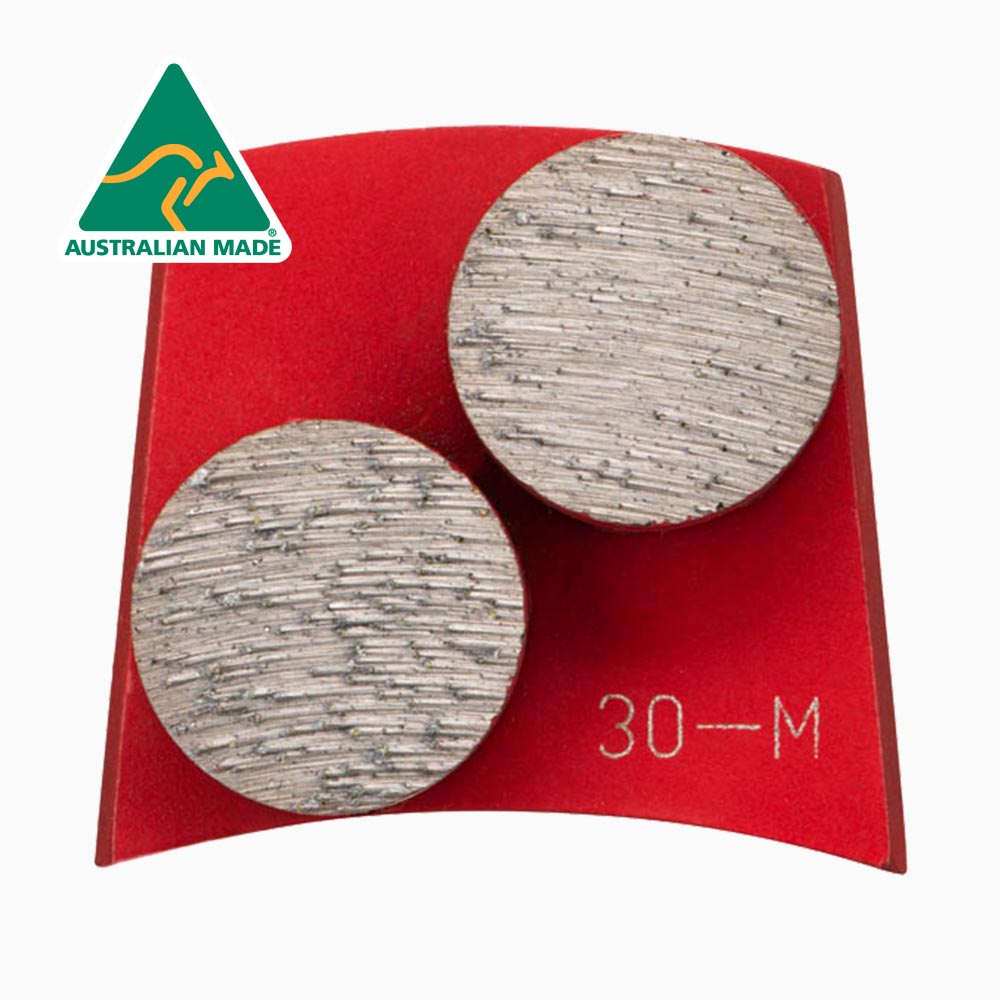

Metal bond diamond segments come in many shapes, including:

- Arrow segments

- Single and double bars

- S-segments

- Single and double round buttons

Each shape influences how the tool engages with the concrete surface. Arrow segments, for example, create a sharp leading edge for aggressive cutting, while round buttons offer a more even grind.

But just as important as shape is the bond type:

- Use soft bond tooling for hard concrete

- Use hard bond tooling for soft concrete

This helps balance wear and cutting efficiency. Pairing the wrong bond with the concrete hardness can lead to early segment wear or ineffective grinding.

Pro Tips for Better Grinding Results

Want to get the most out of your concrete grinder tooling? Keep these tips in mind:

- The finer the grit, the slower your grinder speed should be. Let the diamonds do the work.

- Check your dust collector. If you’re not generating dust, your tooling may not be cutting properly.

- Keep the surface clean. Dust and debris reduce segment contact and create uneven grinding.

- Never polish green or uncured concrete. It may look dry, but polishing too early can damage the slab and your tooling.

Better Tooling = Better Results

Understanding how segment size, shape, and bond affect grinding performance can dramatically improve your surface prep results. Tools like the Rapida segment are designed to give you faster cuts, longer life, and better control, especially on dense or hardened concrete.